21 CFR Part 210 and 211 Guidelines for Compliance

Learn About:

- Adequate written procedures.

- Buildings, facilities, and equipment maintenance.

- Product and process controls.

- Training and reporting requirements.

About This Asset

Discover what federal mandates apply for finished pharmaceuticals and how digitization makes compliance easier.

Trusted By

Ease 21 CFR 210-211 Compliance With MasterControl

With MasterControl quality management system (QMS) and manufacturing execution system (MES) software, you never have to sacrifice compliance to achieve efficiency. Our solutions are designed to ensure compliance with regulatory requirements while also increasing operational efficiency. By natively connecting quality and manufacturing data in one powerful digital tool, MasterControl enhances data connectivity and provides real-time visibility into processes across the entire life cycle of your regulated products.

See what our users are saying

Questions About 21 CFR Parts 210 and 211

Who is required to comply with FDA 21 CFR Part 210 and Part 211?

Pharmaceutical manufacturers that market products in the U.S. are required to comply 21 CFR 210 and Part 211, regulations which outline production practices and controls for finished pharmaceuticals.

What are the key differences between Part 210 and Part 211?

Part 210 outlines cGMP to maintain drug integrity. Part 211 outlines controls for finished pharmaceuticals. Together they provide a framework to safely distribute drugs in the U.S.

How are inspections and audits by regulatory authorities handled under these regulations?

Inspections are used by the U.S. Food and Drug Administration (FDA) uses to ensure that pharmaceutical companies are compliant with regulations. Manufacturers are required to give regulators access.

What are the consequences of non-compliance with Part 210 and Part 211?

Non-compliance with regulations can lead to regulatory actions and sanctions by the U.S. Food and Drug Administration (FDA). Companies risk being prevented from legally marketing products in the U.S.

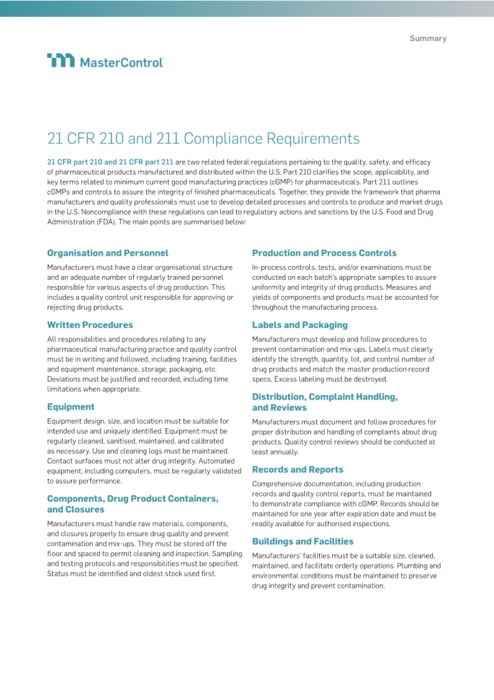

Drug Quality, Safety, and Efficacy Regulations

Pharmaceutical manufacturers must achieve 21 CFR compliance in order to market their products. Major points of 21 CFR parts 210 and 211 are listed below.

-

Written Procedures and Reports

All responsibilities and procedures relating to any pharmaceutical manufacturing practice and quality control must be in writing and followed. Reports must be made available to inspectors.

-

Buildings and Facilities

Manufacturers’ facilities must be a suitable size, cleaned, maintained, and facilitate orderly operations. Environmental conditions must serve to preserve drug integrity and prevent contamination.

-

Equipment

Equipment design, size, and location must be suitable for intended use and uniquely identified. Equipment must be regularly cleaned, sanitized, maintained, and calibrated as necessary.

-

Components, Drug Product Containers, and Closures

Manufacturers must handle raw materials, components, and closures properly to ensure drug quality and prevent contamination and mix-ups.

-

Production and Process Controls

In-process controls, tests, and/or examinations must be conducted on appropriate samples to assure batch uniformity and integrity of drug products.

-

Distribution, Complaint Handling, and Reviews

Prior to distribution, products must clearly identified and traceable. Complaints must be registered and responded to. Quality reviews must be conducted at least annually.

Confused about 21 CFR Part 210 and 211 Compliance?

Get clear on the FDA’s definitions, current good manufacturing practices, and related regulations for finished pharmaceuticals.

Learn about 21 CFR Parts 210 and 211Digital Solutions Supporting Compliance With 21 CFR Part 210 and 211

Digitisation plays a significant role in helping companies adhere to 21 CFR part 210 and 211 guidelines for pharmaceuticals. It also enables manufacturers to modernise their operations, improve efficiency, manage change control, and produce consistently higher-quality products.

-

Data Integrity and Traceability

Digital systems provide robust audit trail capabilities, ensuring the integrity and traceability of data.

-

Change Management

Automated workflows can ensure that changes follow proper approval routes and are implemented consistently, reducing the risk of non-compliance.

-

Training Management

Training materials can be stored, tracked, and assigned based on roles. Automated reminders ensure that personnel stay up -to -date with required training.

-

CAPA Management and Root Cause Analysis

Companies can electronically record and track any quality event, including deviations and non-conformances, as well as automate and route corrective action/preventive action (CAPA) processes.

-

Validation and Compliance

Digitized systems must be validated to ensure they perform as intended and meet regulatory requirements. Reputable software vendors can offer validation tools for use with their products to streamline validation and facilitate more frequent upgrades.

More 21 CFR Part 210 and 211 Compliance Support

Automate Manufacturing Processes

Use electronic batch records to automate core processes, document management activities, promote collaboration, improve decision making, and accelerate time to market.

Choose the Right Compliance Software

Compliant pharmaceutical manufacturing must take place in a controlled environment. Find out how quality management software makes this possible.

Customize Your Compliance Solution

MasterControl has 30 years of experience helping manufacturers and quality professionals get it done right. We’d love to hear about you.