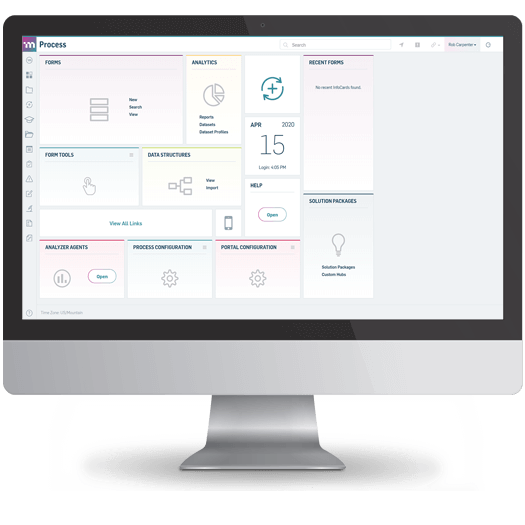

Document control is the key to compliance. MasterControl’s document control software capabilities are unparalleled. The system ensures that documents are always ready for audits. Our solutions streamline compliance by connecting documents and processes across the product life cycle.

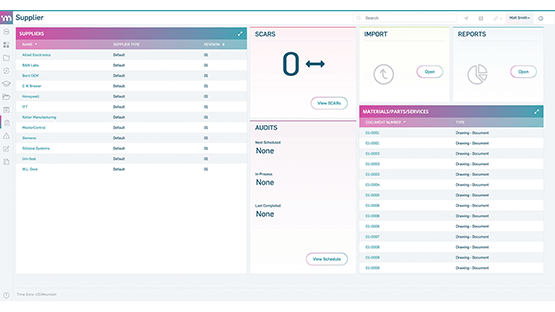

The MasterControl system automatically maintains all supplier status and quality information. The supplier management solution’s user-friendly interface makes it easy to access each supplier’s records and data. The digitally maintained information can be easily compiled into supplier quality ratings.

Most BOM management systems consist mainly of spreadsheets. But manually entering data isn’t only tedious, it’s prone to mistakes, too. Managing BOMs with MasterControl means greater efficiency and fewer errors. The system ensures BOM traceability. It also guarantees that users are only able to access approved BOM documents. That eliminates the use of obsolete documents or unapproved drafts.

Manual production record processes create bottlenecks. They’re also responsible for a vast number of manufacturing errors. Digitization takes the documentation burden off manufacturing and quality teams. MasterControl automates production records to ensure that data is accurately captured. It's been proven to help companies improve key performance metrics and enhance product quality.